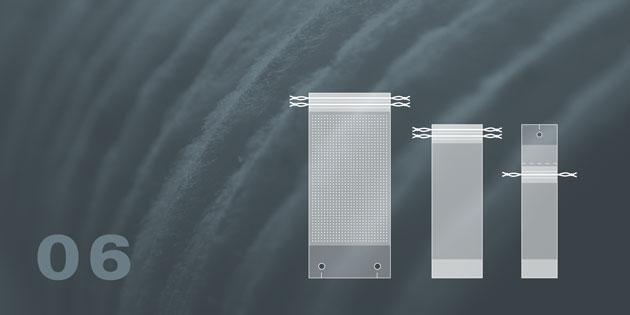

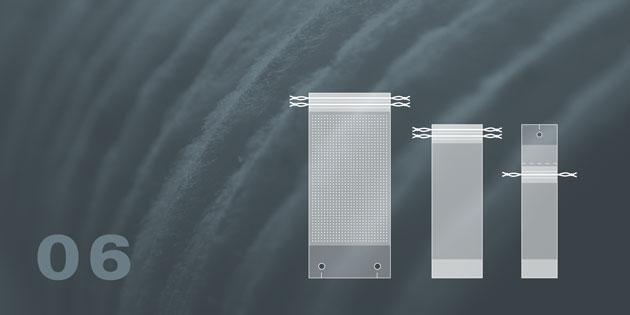

- DRAWSTRING BAGS

- LAUNDRY BAGS

- COTTON WOOL BAGS

- BAGS FOR HAZARDOUS ITEMS

- HOUSEHOLD BAGS

- SHOE BAGS

- FEMININE HYGIENE BAGS

FK 2000 Servo

FOR DRAWSTRING BAGS

FOR DRAWSTRING BAGS

HOLDING RODS

These rods are used to hold a predefined number of wicket bags.

LONGITUDINAL WELDING

A special coating ensures that either no or minimal welding material remains on the finished product (clean welded seam).

FOLDING WHEEL

Used for the creation of folds with a depth of up to 80 mm at the top and / or bottom of the bag.

| Technical DaTA | ||||

| FK 2000/950 OGK | FK 2000/950 GK | FK 2000/1150 OGK | FK 2000/1150 GK | |

| Working width | 615 mm | 615 mm | 815 mm | 815 mm |

| Roll diameter | max. 1.000 mm | max. 1.000 mm | max. 1.000 mm | max. 1.000 mm |

| Bag width | 80 – 450 mm | 80 – 450 mm | 80 – 450 mm | 80 – 450 mm |

| Bag height (B) | 150 – 570 mm | 150 – 450 mm | 150 – 770 mm | 150 – 650 mm |

| Head section height (H) | max. 45 mm | max. 140 mm | max. 45 mm | max. 140 mm |

| Bottom fold (F) | 35 – 80 mm | 35 – 80 mm | 35 – 80 mm | 35 – 80 mm |

| Films | LDPE, PP | LDPE, PP | LDPE, PP | LDPE, PP |

| Film thickness | appr. 2 x 0,015 – 2 x 0,080 mm | appr. 2 x 0,015 – 2 x 0,080 mm | appr. 2 x 0,015 – 2 x 0,080 mm | appr. 2 x 0,015 – 2 x 0,080 mm |

| Speed | max. 40 m / min. | max. 40 m / min. | max. 40 m / min. | max. 40 m / min. |

| Output | max. 150 cycles / min. | max. 150 cycles / min. | max. 150 cycles / min. | max. 150 cycles / min. |

|

|

||||